After batching, the fabric is taken for dyeing at our second site in Elland, West Yorkshire!

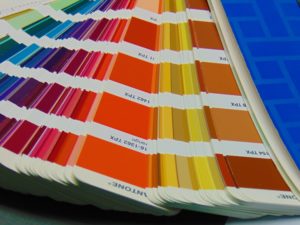

As well as our standard shade range we’re also able to colour match to a cutting or pantone reference. Using state-of-the-art colour matching systems, our lab analyse a customer’s desired shade reference and create a lab dip for approval. Once approved, the recipe is scaled up for the bulk dyeing machinery.

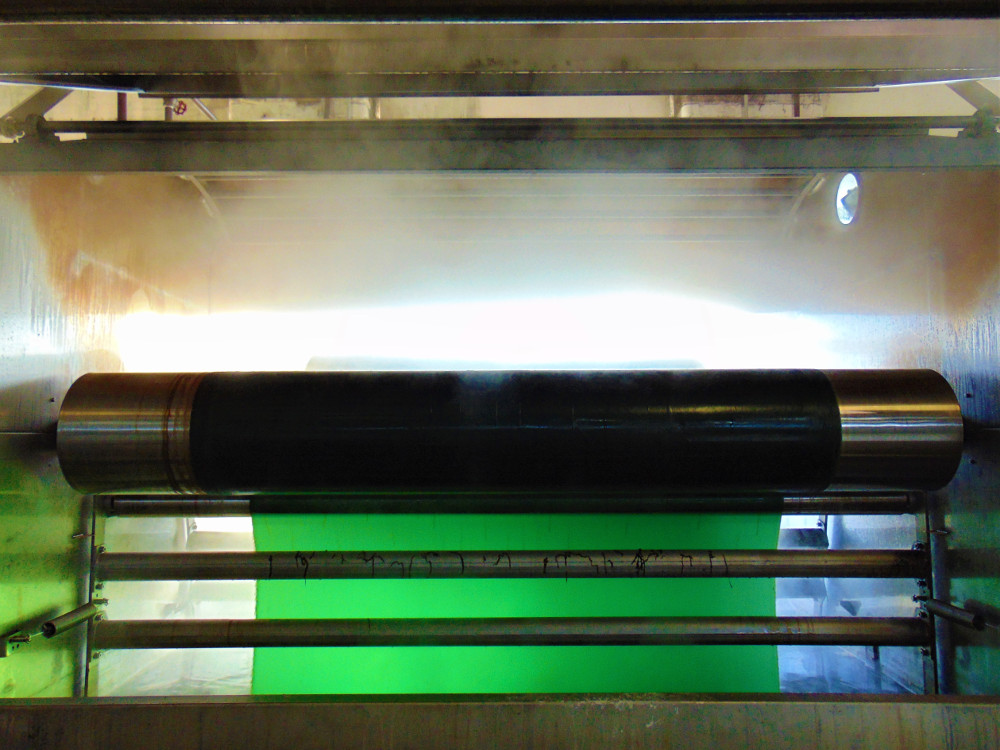

Our Elland site has a number of specialist dye capabilities; the Jig and Cold Pad Batch machines are most commonly used when dyeing our cotton base cloth. Our Cold Pad Batch machine can run up to an impressive 10,000 metres a day, making it a highly productive and efficient piece of kit. The cotton is dyed at room temperature, saving energy and reducing the amount of water used versus other dye methods. Ready to Dye (RFD) fabric is passed round a series of rollers in the bath of dye solution at carefully controlled speed and pressure. After passing through the dye mix, we spin the fabric for up to 24 hours to allow the dye to fully penetrate the cotton fibers in an even distribution across the batch.

Our atmospheric Jig machines are primarily used for loomstate, which requires a little more work than Ready to Dye (RFD) fabric. Up to 2,000m of fabric can be washed ready for dyeing and dyed on the same jig machine – our new digitally controlled jigs allow us to carefully adjust temperatures and dye cycle timings depending on the base cloth weight and specification. The fabric moves many times from one roller two another, through a bath of reactive dye.

After dyeing all fabric goes through a wash cycle on the jig machines to remove excess dye and get it ready to return to our Rochdale site for the next step, Finishing!